Hard Water

December 3, 2021

7 minute ReadBY PAUL KALSCHEUR, PRESIDENT

VELOCITY WATER WORKS

The hard and soft qualities of an object — whether it be a chair, a marshmallow, a rock or your water — decide the ideal purpose and use of that object. But, unlike the other examples, water’s hardness or softness doesn’t just describe its physical appearance and is not an absolute; it can be changed to best fit the situation and the use. This is especially important for car wash operators and owners to recognize, as the degree of hardness or softness in your water can make a big difference in how well your wash cleans cars, the amount of soap required to make them clean, how long your equipment lasts and, ultimately, your bottom line. Here are some questions and answers that provide insights into water hardness and soft water, and some solutions to help ensure your water’s hardness isn’t hurting your business.

WHAT IS WATER HARDNESS AND SOFT WATER?

A general term for water hardness is the level of calcium and magnesium in water. The more hardness in the water, the more negative impact it can have on wash quality. The term ‘water hardness’ actually referred to waters that were ‘hard’ to wash in… or basically, the hardness that prevents soaps from lathering and causing the development of insoluble precipitate. While this definition was originated for residential applications, it is easy to see how water hardness can apply to the car wash industry as well.

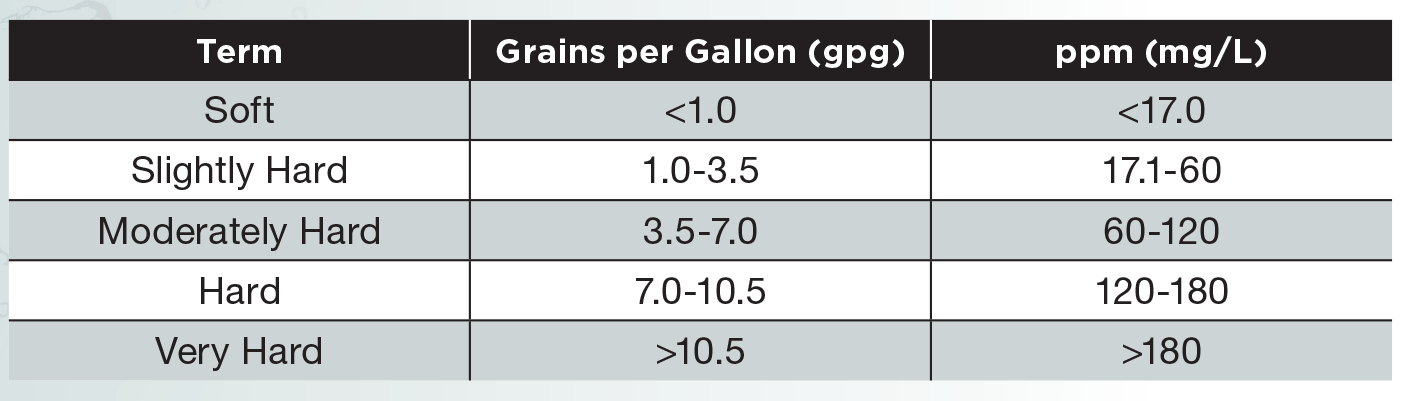

For reference purposes, the WQA (Water Quality Association) defines soft water as water with less than 1 grain per gallon (gpg) of water hardness. Following is a WQA Chart with a hardness level breakdown.

HOW DOES HARDNESS GET IN OUR WATER SUPPLY?

During the precipitation step of the water cycle, water moves through the soil and rock as it works its way into the groundwater supply. During this process, water will dissolve minerals, including calcium and magnesium. The levels of water hardness vary based on different regions of the country. See map below for reference.

Concentration of Hardness as Calcium Carbonate by Milligram per Liter

WHAT PROBLEMS CAN WATER HARDNESS CAUSE?

The more water hardness in a water supply, the more (negative) impact it can have on the performance of wash equipment. Problems with hard water in a car wash include poor chemical performance, reduced equipment performance (pumps, clogged nozzles, RO System production rates, etc).

HOW DOES A WATER SOFTENER WORK?

A water softener uses an ion exchange process to remove troublesome hardness minerals, calcium (Ca2+) and magnesium (Mg2+ ) from the water supply. Basically, hard water travels through a mineral tank filled with a negatively charged ion resin that is fully charged with sodium (Na+) ions. While passing through the resin, hardness ions (Ca2+ and Mg2+) are physically exchanged with the sodium ions. This process continues until the resin becomes saturated (full with hardness ions). At that point, for the softener to continue to function properly, a regeneration of the resin must be initiated. During the regeneration cycle, brine — a brackish water created in the brine (salt) tank by mixing water and salt — is passed through the resin tank. As this brine passes through the tank, sodium ions are exchanged for hardness ions on the resin, and the hardness ions are sent to drain. This process continues until all hardness ions are exchanged with sodium ions.

PROPERLY SIZING A WATER SOFTENER

For a water softener to perform properly, and to provide consistent soft water, it is critical that the water softener to be sized correctly for the application. To properly size the softener, first, it is important to know the quality of the water coming into your wash. There are many knowledgeable water treatment professionals in car wash industry that would be happy to test your water, and provide their suggestions based upon test results. Some car wash operators may need to softener all their water, while others may need to soften water feeding their chemical applications and RO System, and others are fortunate enough that no water softener is required at all.

Mean hardness as calcium carbonate at NASQAN water-monitoring sites. Colors represent streamflow from the hydrologic-unit area. from https://www.usgs.gov/media/images/map-water-hardness-united-states

#1) FLOW RATE:

What is the total flow rate (gpm) of all your soft water applications?

After you have totaled your total soft water flow rate (gpm), the water softener you select must have a service (continuous) flow rate that exceeds the total flow rate of all your soft water applications.

Water softener specifications are usually listed with both service (continuous) flow rates and peak flow rates. It is important that you size your water softener using the service flow rate specifications of a softener because that is the basis for a softener functioning properly.

If your application has a flow rate higher than the softener’s service flow rate, your softener will have an increased pressure drop (minimum of 25psi) and hard water will likely “leak though” the softener due to not enough contact time or the water creating channels in the resin bed.

The flow rate of a softener is dependent on the size of the valve, which usually ranges from 1 inch up to 3 inches. However, in some applications where higher flow rates are required, softeners can have additional tanks added to the softener (triple tank or quad tank) to achieve higher flow rates. Additionally, the softener tank size does have impact flow rates. Tank sizes are also used to size a softener’s capacity, which is discussed below.

#2) CAPACITY (WATER VOLUME).

How many gallons of soft water do you anticipate using each day, and what is the total compensated water hardness of your water? This will determine your capacity used each day.

After you have estimated your total soft water used per day, multiply it by the water hardness of your incoming water supply. This will give you your total capacity used each day. For reference purposes, let say a tunnel site uses a total of 17,500ga of soft water per day, and the water hardness at the site is 15gpg of hardness. That site uses a total capacity of 262,500 grains per day.

When totaling your soft water used per day, be sure to consider soft water feeding the RO system.

Now keep in mind that the mineral (resin) tank(s) of a water softener come in many different sizes, and each tank can hold a different amount of resin. The more resin in a tank, the more capacity that softener has.

The capacity (tank size) of softener will also vary based upon the design of the softener. The two most common types of water softeners are: a single tank softener or a 2-tank, twin alternating softener.

SINGLE TANK SOFTENER:

The water softener must have enough capacity to soften all the soft water used in a day. if not, hardness will leak through the softener, causing chemical and equipment performance problems and, over a longer period, other equipment issues (i.e. clogged nozzles).

2-TANK, TWIN ALTERNATING SOFTENER:

With a twin alternating water softener, each tank does not need to have more softening capacity than the total capacity used each day. This is because the two tanks can alternate between each other, providing soft water 24/7. It is recommended, however, that each tank have enough capacity to get though a minimum of a half a day of washing because of the amount of time it takes for a softener tank to regenerate (usually around three hours when factoring in the creation of a proper brine solution).

When comparing a single tank softener to a twin alternating softener, the main benefit of a single tank softener is the reduced initial investment cost, followed by slightly smaller footprint. The main benefit of a twin alternating softener is that when it is properly operating, the twin softener gives you 24/7 soft water, and is much more efficient than a single tank softener.

For example, if a tank on a twin alternating softener exhausts its capacity in the middle of the busiest wash day, the twin alternating softener will simply alternate to the other tank that has been on stand-by, waiting to go online. With a single tank softener, if the tank exhausts its capacity, hard water will leak through. In order to prevent that hardness leak, newer single tank softeners in the middle of the night will calculate how much soft water capacity they have remaining and compare it to the estimated water usage for the next day. With a twin alternating softener, the operator never has to regenerate with capacity remaining because the minute one tank exhausts its capacity (even during the middle of a busy wash day) your other tank can immediately come online.