Growth Is Skyrocketing for Car Wash Sensors

February 22, 2022

5 minute ReadBy Lindsey Quick

Much like other areas of the technological world, the sensor industry is experiencing a fast-paced advancement of its capabilities. Sensors range in functionality, some operated by touch, some by infrared beams and others by emitted sonar or sound waves. Car wash owners can find sensors for nearly all aspects of their operations, eliminating processes that used to be manual and inefficient. Plus, they are solving problems and saving money for owners and operators in the car wash industry.

“Sensor technology has changed quite a bit in the last decade and is constantly improving,” said Joe Williams, President and CEO of EMX Industries, Inc. Companies today are looking for ways to make sensors easier to use and integrate into a production environment where the sensors can gather information from that environment that is easily and reliably accessible.

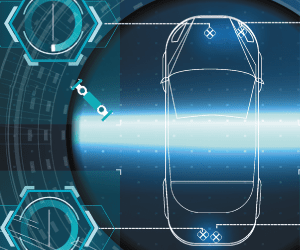

Richard Livengood, President of Telco Sensors USA, echoed those thoughts. “Sensors have evolved from just performing simple tasks, like starting and stopping machinery, to more advanced functions, like positioning and profiling,” Livengood said. “Advanced technologies like light curtains can now create a two-dimensional picture of the vehicle for more accurate top brush placement and identification of vehicle features, such as luggage racks, tow hitches and pickup truck beds.”This means a wash can be customized to the vehicle instead of the one-size-fits-all approach of the past.

SENSORS DESIGNED FOR CAR WASHES

As sensor manufacturers develop new products and functionality for products specifically geared toward the car wash industry, the testing process has been adjusted and adapted to include intricate plans as well as real-world simulations.

“We develop a comprehensive verification and validation test plan to make sure that a new sensor design performs the way we intend,” Williams said. Engineers at EMX Industries build tests to simulate the real-world environment as closely as possible. “Our engineering team used a kiddie pool in the middle of the office to verify that the manufacturing process improvement we made to our Car Wash Pad did not cause any adverse effects to the water resistance of the final product.”

Once the product is ready for production, companies find that one challenge in production is getting the parts because cell phones and many other devices are competing for the same components and are therefore on short supply. But overall, Livengood said the production of sensors has gotten easier.

One challenge Williams sees with many sensor manufacturers is that they want too much technology in one product. “Sometimes I think we get bit carried away and we develop a $700 solution to a $200 problem,” Williams shared. He believes it’s critical to spend time with the customers who will be using the products in order to understand exactly what they need and the price they can afford to pay, before beginning the product development.

WHICH ONE IS RIGHT FOR YOU?

For car wash owners and operators, choosing the right sensors can save both time and money. One option, vehicle detectors, can be used in a variety of locations throughout the wash, all to help save money. Vehicle detectors can be positioned at the entry kiosk to keep the kiosk in a low power “sleep state” until a vehicle approaches. They can also be used under barrier arms to prevent them from coming down on a customer’s vehicle, causing unnecessary damage.

“Multiple vehicle detectors can be used in various places in the car wash to know exactly where vehicles are in the process to start and stop wash systems as desired to conserve resources,” he said.

Other sensor options that Williams suggests include photoeyes, which can be used to set up safety zones for employees to prevent them from getting too close to spinning equipment, and color sensors, which are used to make sure that the proper soap is loaded in the proper supply lines.

-- Richard Livengood, President of Telco Sensors USA

For Livengood, it’s essential to find a trustworthy product that will save money in the long run. “Performance and lifespan are critical to reduce the amount of time your wash is inoperable,” he said. “Lost revenue from downtime often far exceeds the cost of a failed sensor.” He recommends that owners choose a sensor rugged enough to withstand the harsh environments found in a car wash, made by a company with a reputation for reliability and long lifespan. He also suggests that owners ask themselves if the sensors they’re considering have a proven design with years of experience in the vehicle wash industry, a water-tight build and chemical resistance.

Choosing the wrong sensor can result in wasted time and money, as well as customer frustration. Livengood points out that a sensor that fails to perform can result in a minor issue, like longer wait times, or a more serious and expensive issue, like an equipment crash that causes vehicle damage. “Advanced technologies, like the light curtains, are designed to provide a better wash and a cleaner car,” Livengood said.

CONSUMER EXPERIENCE & SUSTAINABILITY

Williams finds that sensors can improve or streamline the consumer experience by providing another avenue for communication. “Sensors could be used in the car wash to let a customer know that the right upgrades they purchased are being applied to their car,” he said. This helps customers feel like they know where they are in the process and helps them understand what’s happening each step of the way.

Like most new and advancing technologies, one aspect that’s especially important in the car wash industry is sustainability. Sensors are the same. The ability of sensors to better detect when a vehicle is entering or leaving the wash, and what kind of vehicle is entering, make a huge difference. “By using non-contact sensors in a car wash to control and decrease wash time or seeing a vehicle’s contour to know where to wash or not to wash, you can save chemicals, water and electricity that were once being wasted,” said Livengood.

EMX Industries feels similarly. “We believe that sensors can be used to reduce waste by activating car wash processes at the exact moment – and only for the amount of time that they are necessary – to produce a clean car,” said Williams.

The technological advancement of sensors in the car wash industry leads to lower costs due to more specialized functionality to enhance the operation of every aspect of the wash, from the moments before a vehicle enters to the time it leaves.

Sensors can detect when a vehicle is approaching, what kind of vehicle it is, what special equipment it might have (which can determine the types of cleaning tools/brushes used and the amount of water and soap needed), and when the vehicle is exiting the wash. All while helping consumers better understand where they are as they progress through the wash.